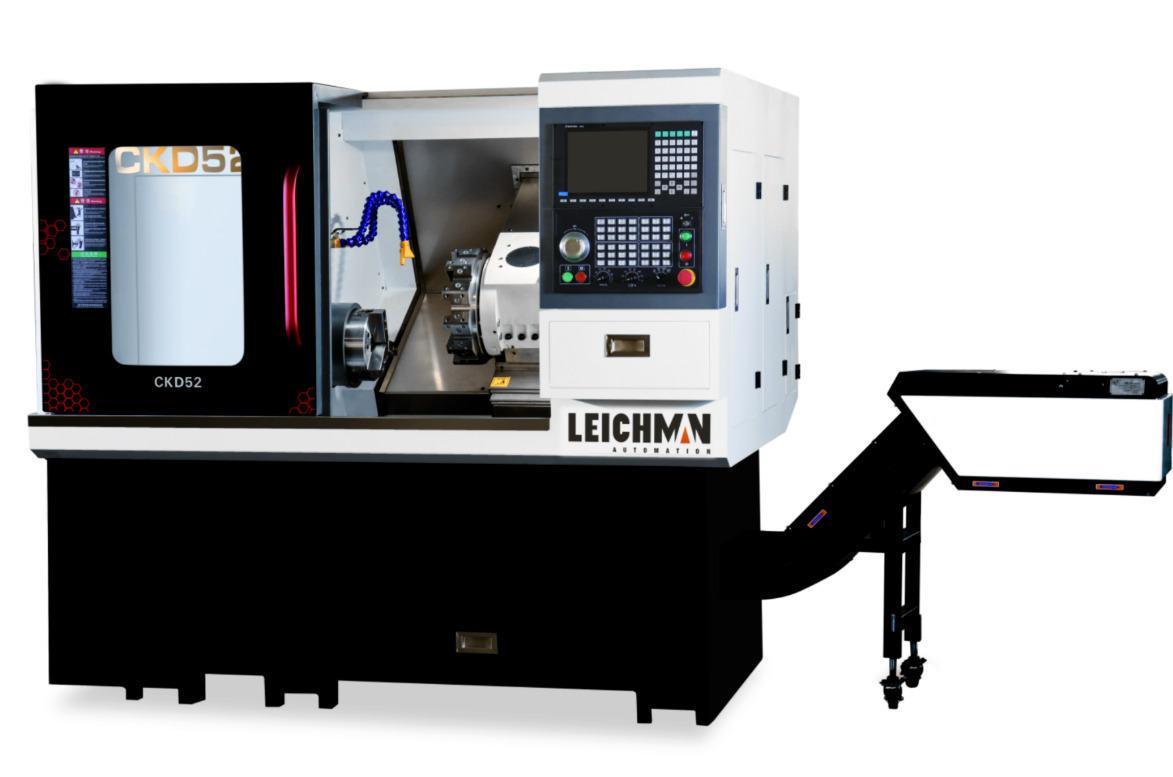

Turret CNC Lathe CKD52

Product Description

Product Description

The CNC Lathe machine tool control system adopts Taiwan SYNTEC system, and it can also be equipped with CNC systems produced by other companies according to user requirements.

The base and bed of the machine tool are integrally cast iron, which has strong shock resistance and is not easy to deform. The bed is inclined at 30°, and the large carriage and tool post are inclined, which makes the operation of the machine tool and chip removal very convenient. The appearance design of the machine tool is beautiful, and it takes up little space.

|

Item |

Unit |

CKD52 |

|

|

Capacity |

Max swing over bed |

mm |

500 |

|

Max. machining diameter |

mm |

480 |

|

|

Max. machining length |

mm |

380 |

|

|

Travel |

X axis travel |

mm |

250 |

|

Z axis travel |

mm |

400 |

|

|

Precision |

Spindle runout |

mm |

0.004 |

|

X/Z axis reposition precision |

mm |

0.002 |

|

|

Spindle |

Spindle speed |

rpm |

4000 |

|

Chuck diameter |

inch |

8 |

|

|

Spindle nose |

|

A2-6 |

|

|

Spindle bore |

mm |

63 |

|

|

Max bar diameter |

mm |

52 |

|

Slant Bed CNC Turret Lathe with Tailstock|CNC Lathe with X Z Axis

The main shaft adopts a high-precision main shaft, which contains Swiss SKF precision main shaft bearings. The main shaft flange can be directly installed with a three-jaw self-centering hydraulic chuck or other elastic chuck.

The transmission part of the machine tool adopts the high-precision Japanese THK ball screw and high-speed linear slide of the well-known Japanese THK 35-type. The X-axis and Z-axis adopt the high-rigidity linear slide, and the track and the track are optimized through calculation. Span, low resistance, high rigidity, high precision, displacement speed up to 24m/min, provide work efficiency and shorten processing time.

More information please click: www.leichman.cc